VISIT US

ITMA 2023

H11

STAND B102

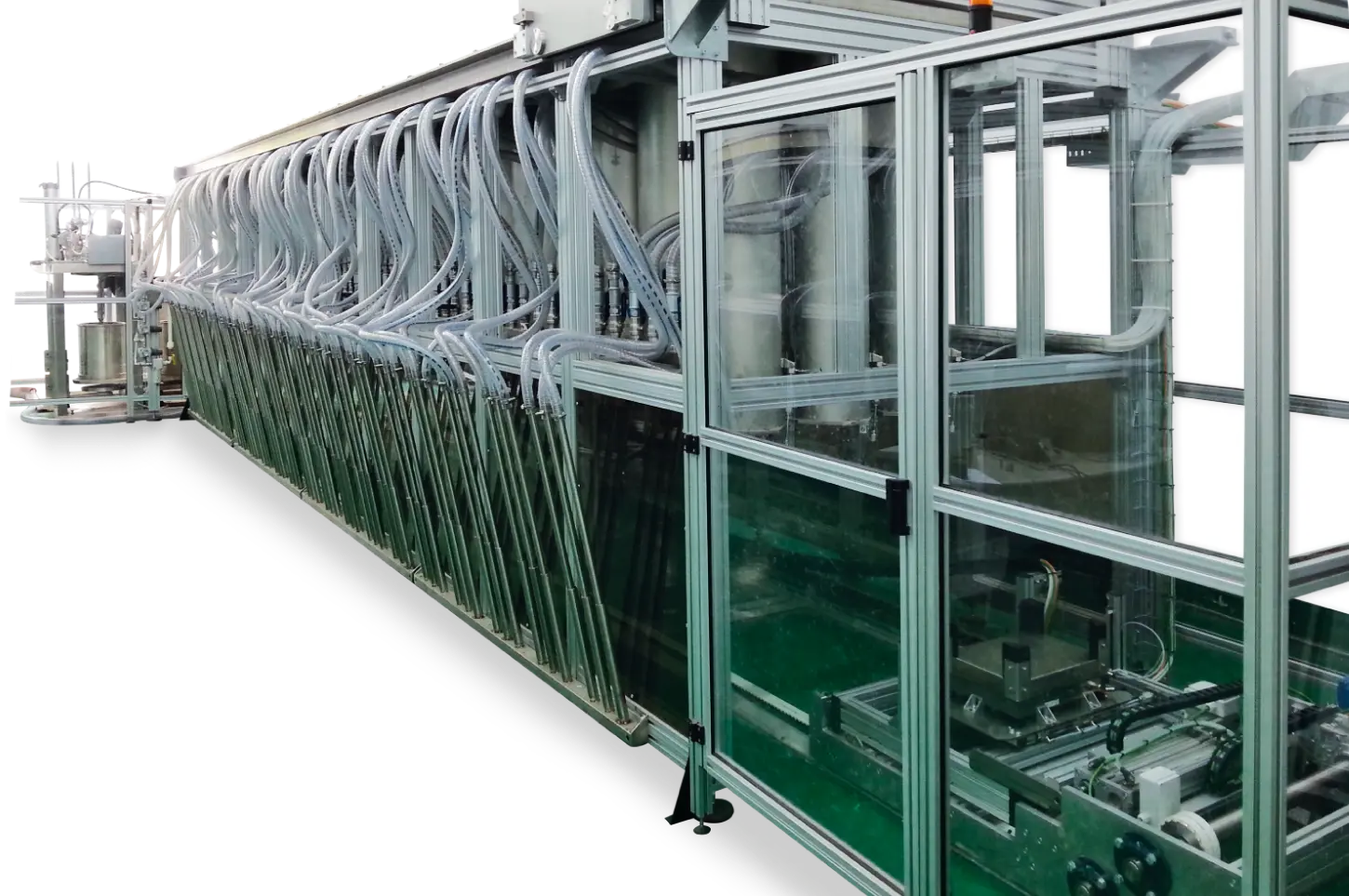

TECNORAMA® develops and produces completely automatic dyeing systems both for lab and bulk trough the combination and integration of automatic dispensing machines with special robotized dyeing machines to dye any textile material.

Our highlights news

Satisfaction with these 40 years, high expectations for the future

Another prestigious award for Tecnorama as Italian excellence

Join us at the booth of our agent Sigma, at Jakarta from 15 to 17 April 2025

Meet us during the fair at Lahore, Pakistan, from 24 to 26 April 2025

Meet us at Atlanta during the exhibition - ACIMIT booth - from 6 to 8 May 2025

Meet us during the fair at Singapore, from 28 to 31 October 2025 - Hall H7, booth A413

Pakistan Textile Journal - December 24

Textile Magazine September 24 issue

Indian Textile Magazine interview to Mr.Giugni - CEO of Tecnorama

TekstilNews

A global milestone in color innovation

Another prestigious award for Tecnorama as Italian excellence

Satisfaction with these 40 years, high expectations for the future

Join us at the booth of our agent Sigma, at Jakarta from 15 to 17 April 2025

Meet us during the fair at Lahore, Pakistan, from 24 to 26 April 2025

Meet us at Atlanta during the exhibition - ACIMIT booth - from 6 to 8 May 2025

Meet us during the fair at Singapore, from 28 to 31 October 2025 - Hall H7, booth A413

Pakistan Textile Journal - December 24

A global milestone in color innovation

Indian Textile Magazine interview to Mr.Giugni - CEO of Tecnorama

Textile Magazine September 24 issue

TekstilNews

Some of our esteemed clients