DYRAMA

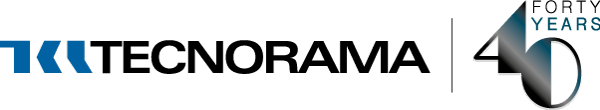

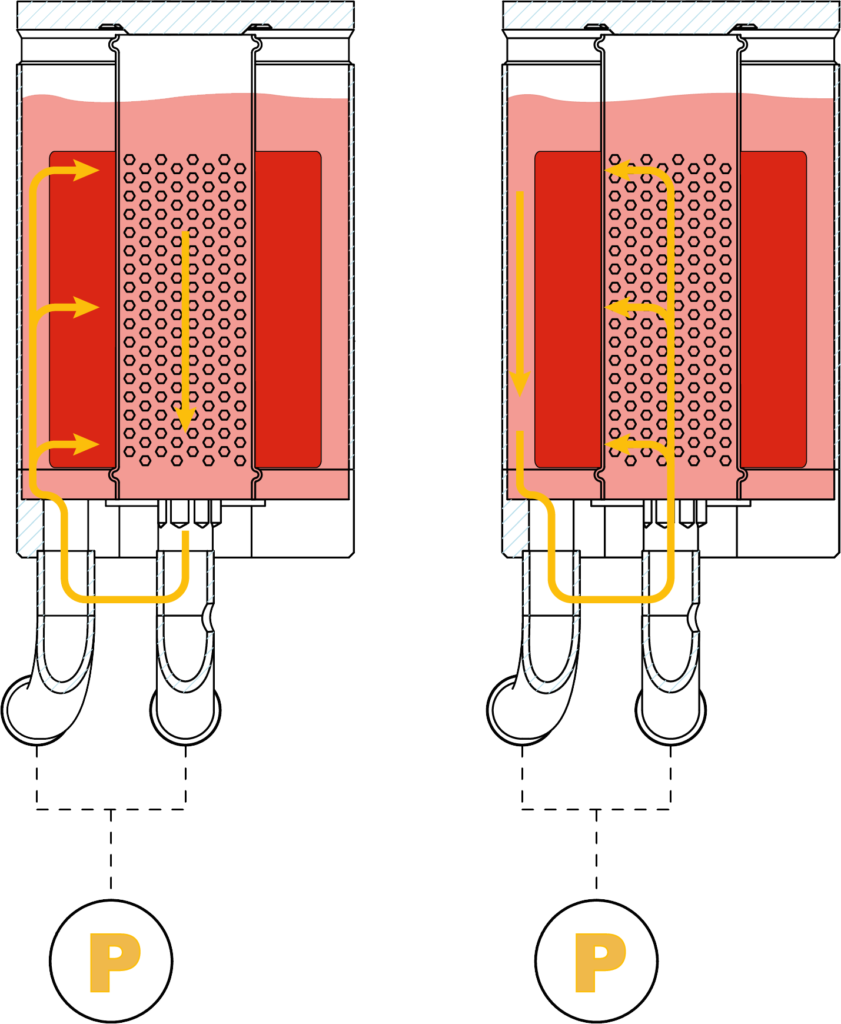

Dyeing modules with forced bath circulation by means of pump and individual kiers particularly suitable for yarn dyeing. Reversible pump circulation system, external-internal, internal-external circulation

LAB > DYEING MODULES

The DYRAMA is a module with 6 or 8 individual dye-kiers, to process samples from 50 up to 500 grams, according to the liquor ratio (from 1:6 up to 1:20). The bath circulation is obtained through a reversible pump (internal/external and external/internal) and the pump speed is controlled by means of an inverter.

Each single dye-kier is managed by an individual program. The maximum working temperature is 140°C, reachable through an electrical resistance (jacket) and the cooling is indirect by forced water circulation.